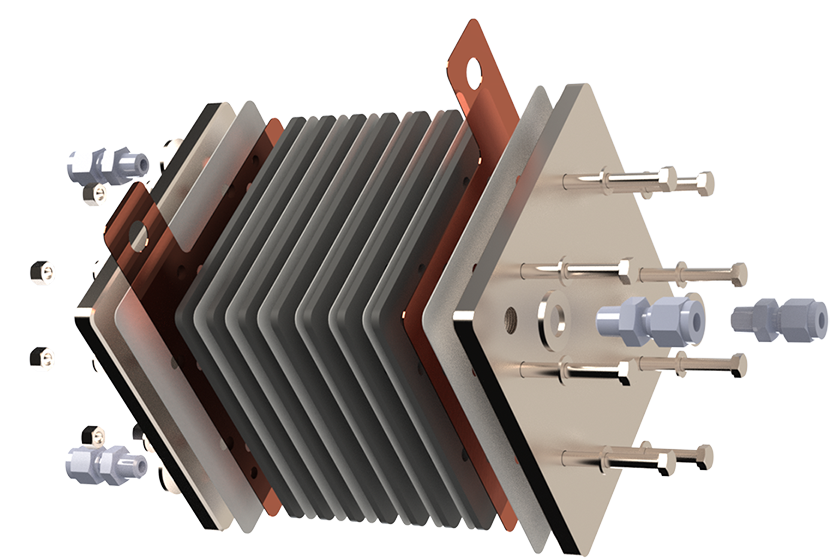

We have developed and patented the most disruptive technology for the generation of green hydrogen through water electrolysis, being able to generate hydrogen where others cannot. This factor, together with the use of the by-products of the process through a totally circular operation, allows us to generate other high-value products and solutions with a single system, which places us among the most innovative technological solutions on the market.

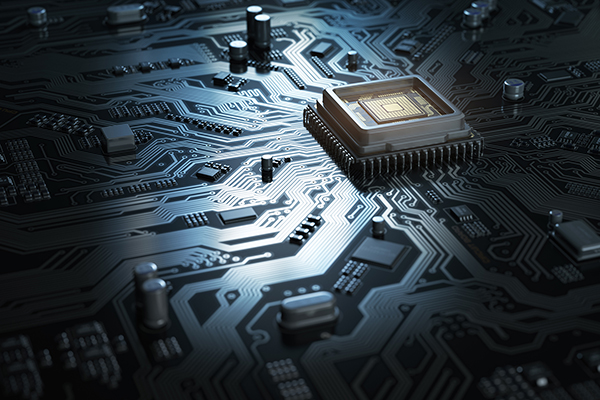

Water2kW has in its DNA the development and constant improvement of disruptive solutions. We are already taking the first steps towards new challenges and objectives, aimed at the implementation of artificial intelligence solutions, new less expensive and more environmentally friendly materials and the modeling and simulation of advanced processes. This set of actions will allow us, in a short period of time, to lower production costs and increase the efficiency, safety and reliability of electrolysis technology to levels not achieved until now by the industry.

In the next two years we will intensify R&D&i activities in key aspects. The data we currently manage makes us optimistic and brings us closer to the goal of achieving, with our technology, consumption of less than 20kWh per kilogram of green hydrogen produced.